arduino load cell 로드셀

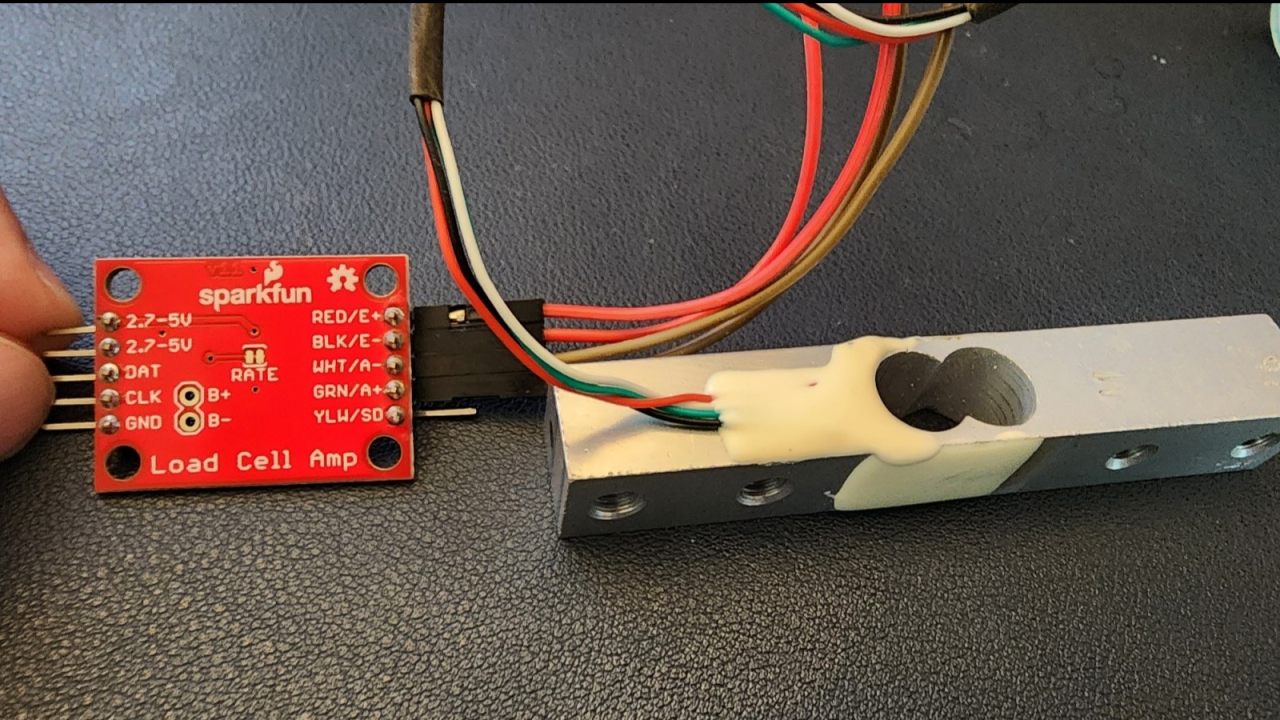

| Load cell | HX711 | 명칭 |

| RED | E+ | 전원+ |

| BLK | E- | 전원- |

| WHT | A- | 신호- |

| GRN | A+ | 신호+ |

| YLW | SD | 차폐 와이어(shield) |

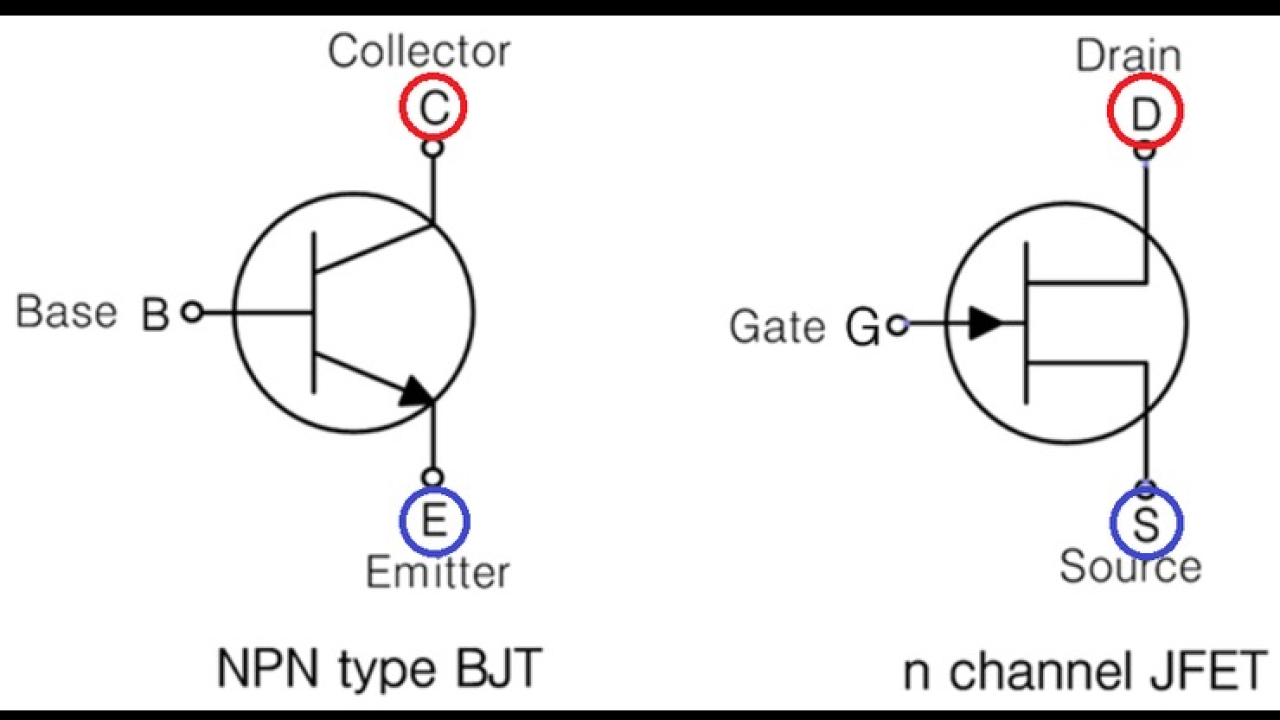

- Vcc : collector

- Vdd : drain

- Vee : emitter

- Vss : source

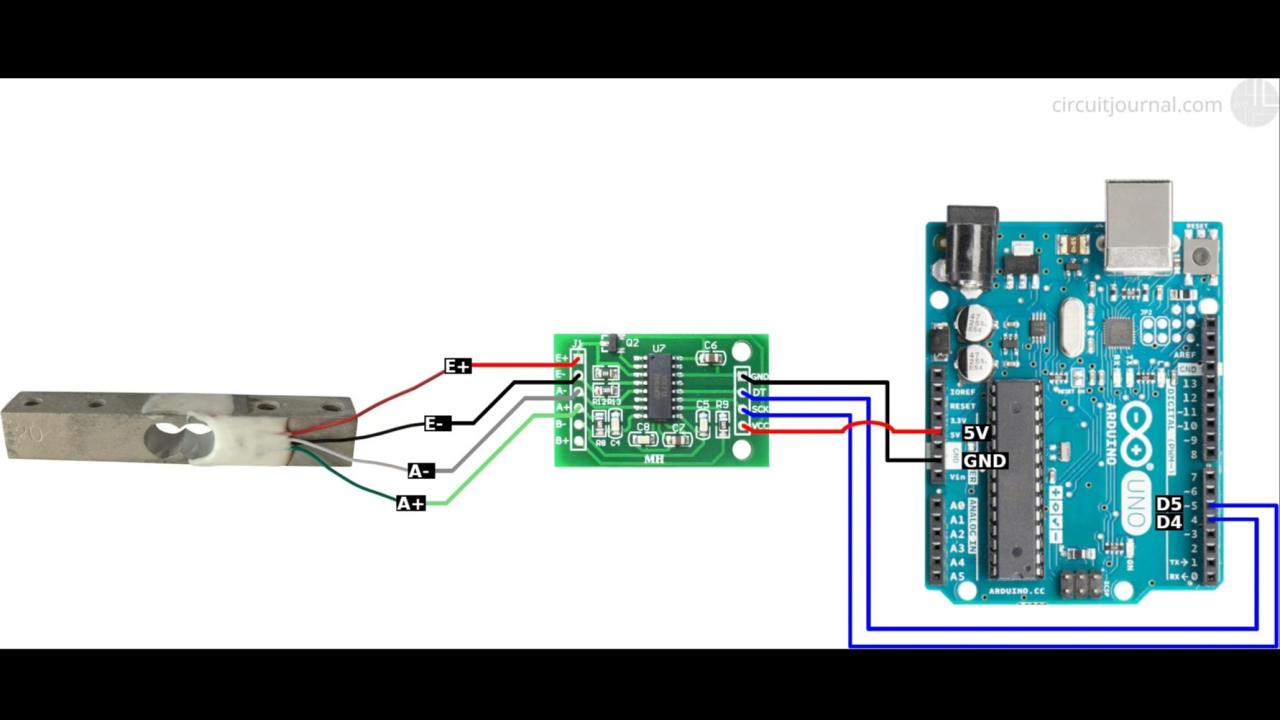

| Load cell | arduino | 명칭 |

| GND | GND | 전원- |

| DAT | D4 | 데이터 |

| CLK | D5 | 클럭 |

| VCC | 5V | 전원+ |

| VDD | 5V | 전원+ |

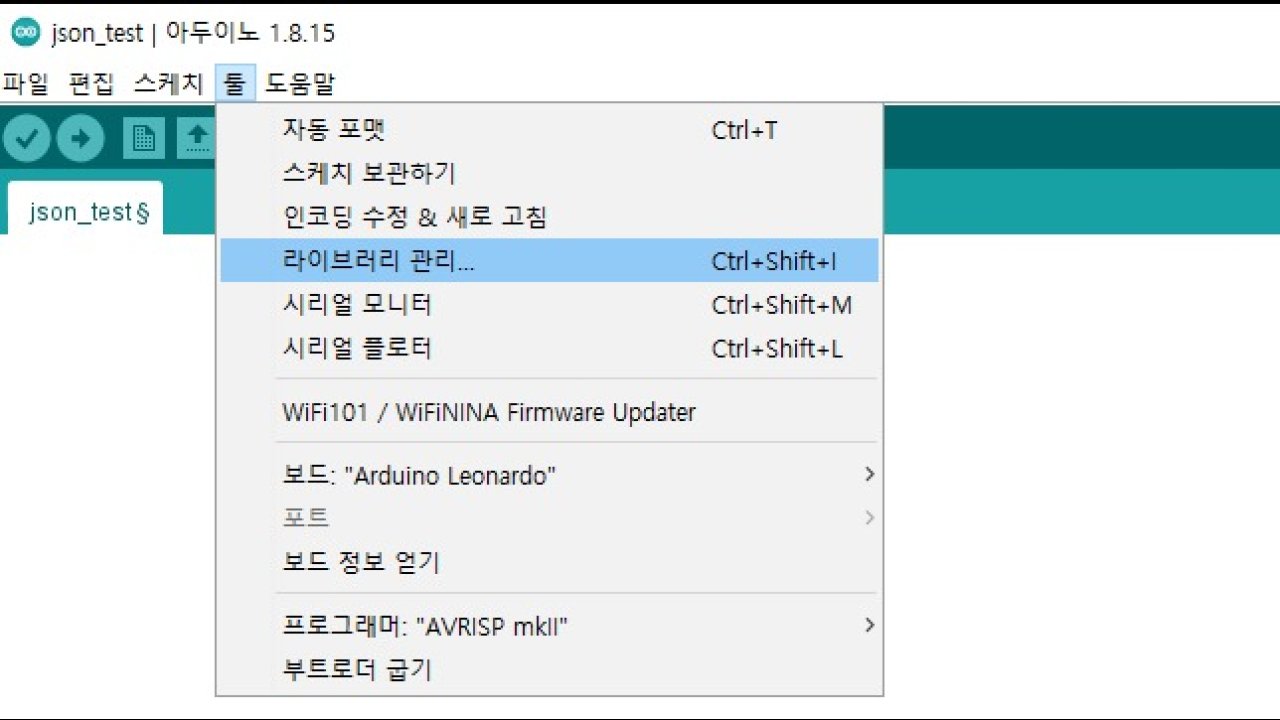

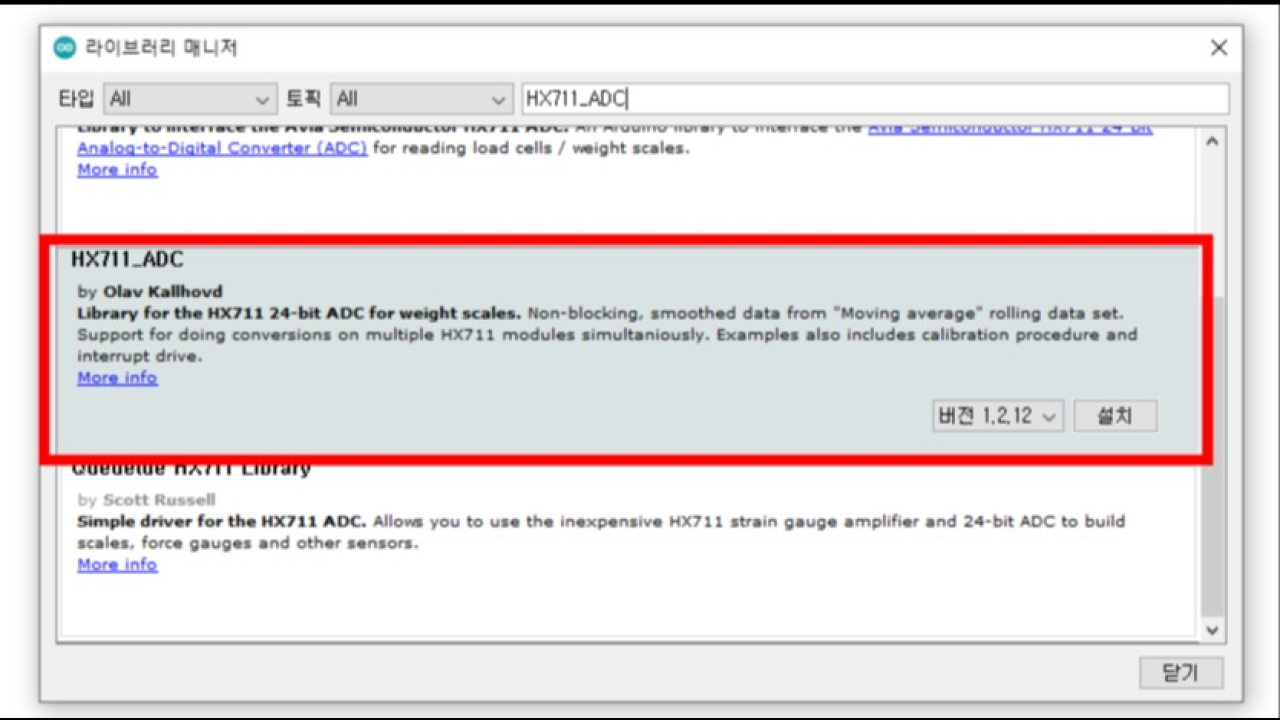

- https://github.com/olkal/HX711_ADC

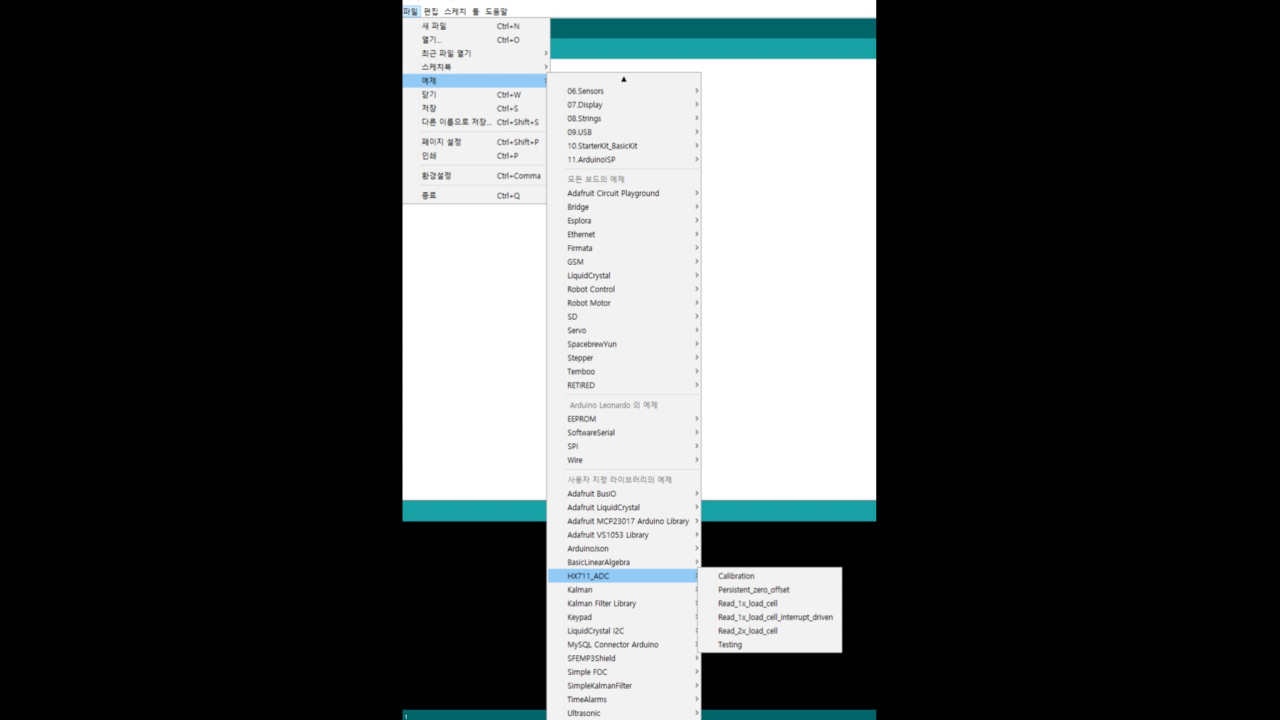

- File->Examples->HX711_ADC->Calibration

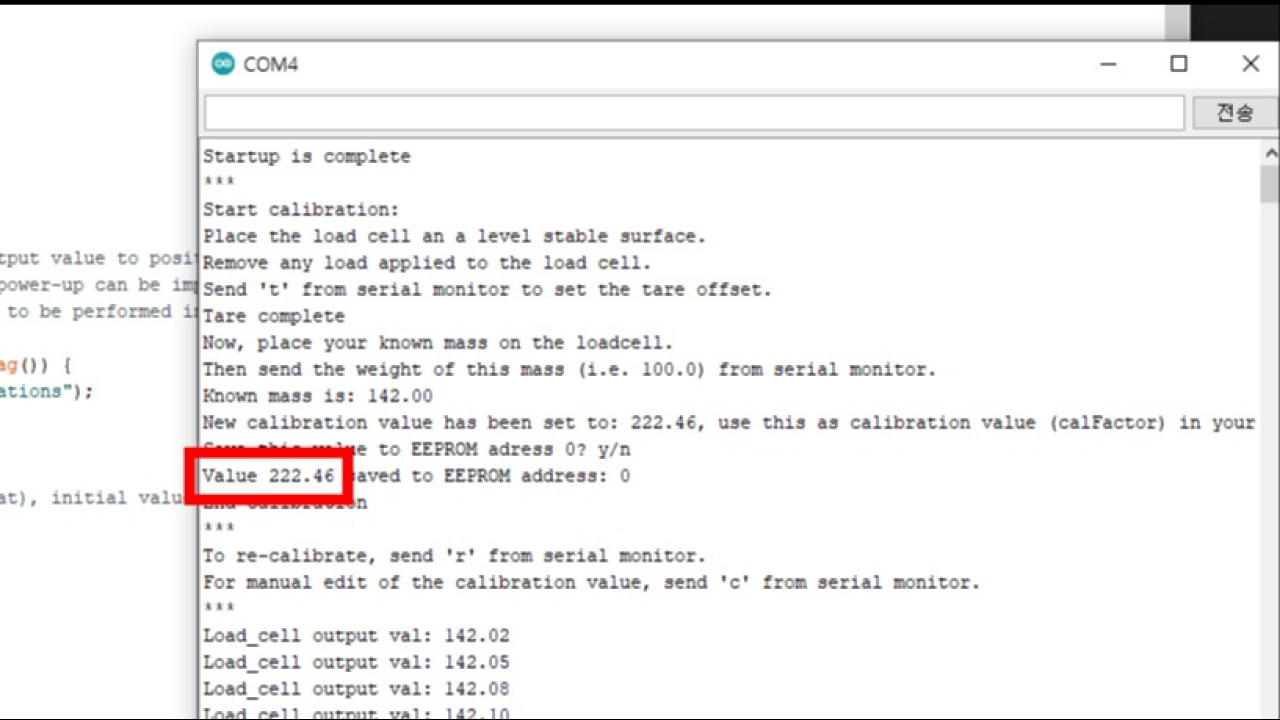

- 시리얼 모니터에 T를 입력하여 켈리브레이션 시작

- 무게를 알수 있는 물체를 준비하여 로드셀 위에 얹고 무게를 입력

- Y를 입력하여 EEPROM에 켈리브레이션 값 기록

- 켈리브레이션을 마치고 나면 켈리브레이션 값을 얻을 수 있음

#include <HX711_ADC.h>

#if defined(ESP8266)|| defined(ESP32) || defined(AVR)

#include <EEPROM.h>

#endif

#define HX711_dout 4 //HX711 데이터핀

#define HX711_sck 5 //HX711 클럭핀

//HX711 constructor:

HX711_ADC LoadCell(HX711_dout, HX711_sck);

const int calVal_eepromAdress = 0;

unsigned long t = 0;

void setup() {

Serial.begin(57600); delay(10);

Serial.println();

Serial.println("Starting...");

float calibrationValue; // calibration value

calibrationValue = 222.46; //직접값을 입력 (EEPROM데이터가 있다면 덮어씌어짐)

#if defined(ESP8266) || defined(ESP32)

EEPROM.begin(512);

#endif

EEPROM.get(calVal_eepromAdress, calibrationValue);

//캘리브레이션 데이터가 있다면 EEPROM에서 가져옴.

LoadCell.begin();

//LoadCell.setReverseOutput();

unsigned long stabilizingtime = 2000; //용기무게 측정 정밀도 향상을 위한안정화시간

boolean _tare = true; //용기무게 측정이 필요치 않으면 false

LoadCell.start(stabilizingtime, _tare);

if (LoadCell.getTareTimeoutFlag()) {

Serial.println("Timeout, check MCU>HX711 wiring and pin designations");

}

else {

LoadCell.setCalFactor(calibrationValue); // set calibration factor (float)

Serial.println("Startup is complete");

}

while (!LoadCell.update());

Serial.print("Calibration value: ");

Serial.println(LoadCell.getCalFactor());

Serial.print("HX711 measured conversion time ms: ");

Serial.println(LoadCell.getConversionTime());

Serial.print("HX711 measured sampling rate HZ: ");

Serial.println(LoadCell.getSPS());

Serial.print("HX711 measured settlingtime ms: ");

Serial.println(LoadCell.getSettlingTime());

Serial.println("Note that the settling time may increase significantly if you use delay() in your sketch!");

if (LoadCell.getSPS() < 7) {

Serial.println("!!Sampling rate is lower than specification, check MCU>HX711 wiring and pin designations");

}

else if (LoadCell.getSPS() > 100) {

Serial.println("!!Sampling rate is higher than specification, check MCU>HX711 wiring and pin designations");

}

//자체적으로 켈리브레이션을하고 센서 상태를 확인함

}

void loop() {

static boolean newDataReady = 0;

const int serialPrintInterval = 500; //increase value to slow down serial print activity

// check for new data/start next conversion:

if (LoadCell.update()) newDataReady = true;

// get smoothed value from the dataset:

if (newDataReady) {

if (millis() > t + serialPrintInterval) {

float i = LoadCell.getData();

Serial.print("Load_cell output val: ");

Serial.println(i);

newDataReady = 0;

t = millis();

}

}

if(i > 5000){ //로드셀로 부터 입력된 값이 5000그람(5KG)보다 크다면

//모터정지

}else{

//모터회전

}

// receive command from serial terminal, send 't' to initiate tare operation:

if (Serial.available() > 0) {

char inByte = Serial.read();

if (inByte == 't') LoadCell.tareNoDelay();

}

// check if last tare operation is complete:

if (LoadCell.getTareStatus() == true) {

Serial.println("Tare complete");

}

}